Ultimate Guide to Mastering Every Cleanroom Classification

Let's Begin with the Cleanroom Basics

Cell phone circuit boards. Skin care products. A car’s air bag. A life-saving vaccine. None of these products could be put to market unless they were manufactured in an efficient cleanroom system.

What is a cleanroom?

Cleanrooms are controlled environments used in research and manufacturing settings.

The room is designed and maintained to limit the number of particles per cubic meter of air. If your product could be harmed by contaminants, you will likely need a cleanroom. However, not all cleanrooms are created equally.

The type of cleanroom you require will depend on your industry and how you plan to use your cleanroom.

We're here to help you become well-versed in the best practices for the entire cleanroom experience, especially with the intricacies of cleanroom classifications at each and every level.

This guide is your go-to resource for understanding cleanroom classifications, which will ultimately make you an expert in cleanroom specifications and technology.

Setting the Stage on Cleanroom Classifications

Car parts and electronics both require cleanroom systems to fabricate safe, reliable products. However, electronics that use nanotechnology are far more sensitive to temperature, humidity and static electricity, and require a stricter cleanroom environment.

That’s where cleanroom classifications come into play.

Cleanroom standards are dictated by The International Organization for Standardization (ISO), a collaboration between experts in various fields to maintain agreed-upon standards.

The ISO standards for cleanrooms fall under ISO 14644-1 , which defines nine distinct cleanroom classes according to the number of particles per cubic meter by micrometer size.

The ranking system ranges from ISO 9 (the “dirtiest”) to ISO 1 (the “cleanest”).

An ISO 9 cleanroom is cleaner than a regular room, but the concentration of airborne particulates equates to ordinary room air.

ISO 1 cleanrooms are rare and follow the strictest guidelines.

All cleanrooms follow the same basic principles to protect the products and processes in their space.

What's a cleanroom exactly?

A cleanroom only serves its purpose if it consistently maintains a certain standard of cleanliness. The condition of your cleanroom can mean the difference between product success and failure.

There are three main factors to consider for cleanrooms of any classification: surfaces, air flow, and employee access.

- Surfaces | All cleanroom surfaces should be smooth, impervious to microorganisms, and compatible with the approved cleaning agents and disinfectants.

- Air Flow | A heating, ventilation, and air conditioning (HVAC) system should regulate temperature and humidity in the cleanroom. HVACs also use high efficiency particulate air (HEPA) filters to remove particles from the space and pressurize the cleanroom. When the air pressure in the room is greater than the pressure outside, the contaminated air is pushed out of the room through vents, filtered, and recirculated. Cleaner cleanrooms require more air exchanges per hour in order to meet classification standards.

- Employee Access | Since humans are the biggest culprits for bringing contaminants into a cleanroom, it is essential to train all personnel on cleanroom systems. Employees should know the proper procedures for entering and exiting the cleanroom, protective clothing, and handling equipment. Cleanrooms classified as ISO 8 or cleaner will need airlocks for employees and equipment to transition to and from the space. Cleanrooms should only be cleaned by specially trained personnel using approved cleaning solutions and equipment.

Understand the cleanroom requirements & standards

ISO cleanroom classes provide a blueprint for how a cleanroom should be designed and maintained.

The cleanroom classifications set the maximum allowable particles per volume of air in the cleanroom. Air particles are measured in micrometers or microns. The classification system also recommends the number of air changes per hour each class of cleanroom should maintain.

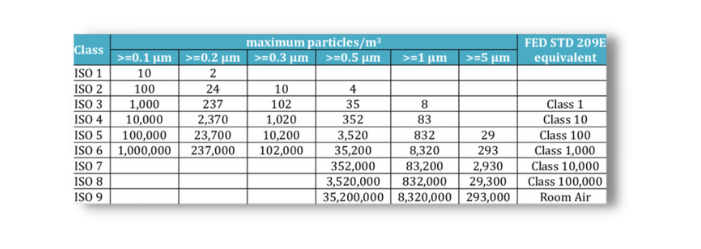

The chart below displays the

ISO 146444-1 cleanroom standards

according to the quantity and size of particles per volume of air allowed for each cleanroom classification.

The cleanroom specifications for an ISO 1 cleanroom are extremely rigid.

The cleanroom’s HEPA filters must remove particles smaller than a speck of dust and accommodate 500-750 air changes per hour.

On the other end of the spectrum, an ISO 7 clean room does not take particles smaller than 0.5 microns into account, and only recommends 30-60 air changes per hour.

Cleanroom manufacturers design many different types of cleanrooms. The cleanroom designs vary depending on the industry, their applications, and ISO cleanroom standards. Some of the variables to consider when deciding on the best type of cleanroom to meet your needs are ventilation methods, air pressure, and modular construction.

Ventilation Methods

In a unidirectional flow room, high efficiency filters that supply air are placed all along the ceiling or wall. The air flows across the room in a unidirectional way, sweeping away airborne contaminants.

A turbulently vented room uses air diffusers in the ceiling to filter the air. The clean air mixes with the room air, removing contaminants through air extracts in the bottoms of the walls.

Air Pressure

In a positive pressure cleanroom, the product or sample needs to be protected from the outside environment. This type of cleanroom requires a unidirectional flow ventilation method.

In a negative pressure cleanroom, personnel and the cleanroom environment need to be protected from a potentially hazardous sample. Negative pressure cleanrooms utilize exhaust vents to remove dangerous chemicals or powders.

Modular Construction

The two varieties of modular cleanrooms are hard wall and soft wall.

Hard wall cleanrooms are constructed with rigid walls set between posts. They provide a high level of control over contaminants, static, pressure and humidity, and are well suited for the stricter ISO cleanroom classes.

Soft wall cleanrooms can be made by fabric pulled taut in a frame or plastic strips that hang from a fixture. This option is more affordable and more versatile than a hard wall cleanroom.

The top industries that use cleanrooms

Cleanrooms are often associated with the life sciences and pharmaceutical fields, but cleanroom manufacturing is actually vital to a diverse range of industries.

- Pharmaceutical, Biology, and Biotechnology | Organic matter is highly susceptible to contamination and requires a rigid cleanroom environment. The slightest contamination from any unwanted source can lead to inaccurate results and a compromised product. Pharmaceutical cleanrooms and cleanrooms in the life sciences field are most often specified between ISO Class 5 and Class 8.

- Government and Military | Government agencies are on the front lines of innovation and new technology. Cleanrooms are necessary for various government projects and experiments. Sure Bio-Chem Laboratories holds SBA HubZone 8A and many other distinct certifications, which makes us an ideal partner for government agencies .

- Manufacturing | Certain manufacturing processes require a high level of environmental control in order to maintain the integrity of the product. Manufacturing in a cleanroom environment ensures cleanliness and consistency in production and testing.

- Medical Devices | Medical devices are classified based on their risk to the patient . Class I is the lowest risk and includes items such as medical tape and bandages. Class III is the highest risk and includes devices that sustain human life such as pacemakers. Class I and II devices are typically manufactured in ISO 7- 8 cleanrooms, but Class 3 devices require more stringent conditions.

- Cosmetics | The cosmetics industry is versatile, utilizing cleanrooms for manufacturing cosmetic products, laboratory analysis, and research and development.

- Food Manufacturing | The Food and Drug Administration (FDA) requires that facilities handling food and drugs refer to ISO 14644 for cleanroom construction and maintenance, specifically for maintaining clean air levels with HEPA filters. Cleanroom classifications vary depending on the sensitivity of different food products to contamination, but commonly meet ISO 6 standards.

- Electronics | Electronics are sensitive to temperature, humidity, and static electricity. Cleanrooms dedicated to electronics production must be immaculate. You are mostly likely to find Class 1 cleanroom standards for electronics that require nanotechnology.

What's it Like to Work in a Cleanroom?

Working in a cleanroom requires specialized training and attention to detail.

The biggest threat to the cleanroom environment are the humans that enter the space. Cleanroom technicians and other personnel working in a cleanroom risk bringing dust, dirt, microorganisms, and other contaminants into the cleanroom. That’s why employees follow strict protocols for carrying out their work in the cleanroom.

Cleanroom technicians prepare for the cleanroom before they even arrive to work. They must remove accessories such as jewelry, makeup, perfume, eyelash extensions, and nail polish that could compromise the cleanroom. Cleanroom technicians should also shower the day they enter the cleanroom.

Before entering the cleanroom, technicians typically wash their hands, step on a sticky mat to remove debris, and follow specified gowning procedures.

The cleanroom may also come equipped with an airlock chamber, gowning room, or air shower to further decrease the chance of outside contaminants entering the cleanroom environment.

While inside the cleanroom, technicians follow specified protocols to complete their tasks. This includes walking through the room slowly, limited talking, and cleaning the equipment.

When it is time to exit the cleanroom, technicians remove protective clothing in the opposite order it was donned.

Who works in a cleanroom?

The U.S. Bureau of Labor Statistics projects approximately 174,200 openings for assemblers and fabricators each year over the decade.

Advances in technology and automation have reduced the need for unskilled assembly workers.

However, demand remains for skilled assembly workers such as cleanroom technicians. Technicians with cleanroom experience perform complex tasks that machines cannot handle.

Many companies require cleanroom technicians to hold a high school degree or GED and offer on-the-job training.

Cleanroom technicians should be detail oriented and have good manual dexterity to handle intricate cleanroom tasks. Technicians can also pursue certifications to gain cleanroom experience and expertise in this field.

Understand cleanroom air and quality standards

Identifying and controlling sources of contamination

An essential task for cleanroom technicians is monitoring the cleanroom air. Invisible particulate matter such as dust, dirt, dead skin, microorganisms and mold are ticking timebombs in the cleanroom environment.

Your cleanroom requires routine monitoring to ensure it remains in compliance with Good Manufacturing Practice (GMP) standards and ISO 14698-1 standards .

It’s impossible to eliminate all particulate matter from the air. Rather, the goal is to keep particle counts within acceptable standards according to cleanroom specifications.

Positive pressure in cleanrooms helps protect the space from external contaminants by pushing air out of the room to be filtered and recirculated. HVAC systems move air through HEPA filters to remove unwanted particles.

Your ISO cleanroom classification will recommend how many air exchanges per hour are necessary to meet cleanroom requirements.

ISO 14698-1 recommends using active air samplers to monitor cleanroom air. Active air samplers draw in specified volumes of air and quantify the number of microorganisms in the sample. This ensures a consistent and high quality cleanroom environment.

Microorganisms spread easily and can survive in harsh environments, which makes them difficult to control.

The most common type of cleanroom contamination comes from water, air, materials, equipment, the facility, and of course, people.

This video explores the sources of contamination you need to keep on your radar in order to protect your cleanroom environment.

Advanced labs like Sure Bio-Chem Labs offer comprehensive microbial monitoring services pinpoint any sources of contamination so you can gain control of your cleanroom.

The Most Common Misconceptions & Myths About Cleanrooms

Cleanroom classification is a highly specialized system.

When cleanroom manufacturers and workers are not fully versed on the standards and recommendations, they can harbor misconceptions that lead to faulty cleanroom practices.

Misconceptions can also lead you to overcompensate your cleanroom needs, resulting in unnecessary costs and labor.

Here are some common myths about cleanrooms and the realities that result in more efficient cleanroom systems.

Myth

: HEPA filters do not work on small particles.

Reality

: HEPA filters commonly advertise their efficiency at stopping 99.99% of particles 0.3 microns or larger. However, they also effectively capture smaller particles, including bacteria and viruses.

Myth

: Cleanroom air must be kept at low humidity levels to prevent microorganisms from growing.

Reality

: Cleanrooms should consistently maintain relative humidity levels of 30%-40% year round. Inconsistent or long term high humidity levels will create problems in your cleanroom.

Myth

: Cleanrooms with more airlocks are cleaner.

Reality:

While airlocks are effective tools for keeping outside contaminants from entering the cleanroom, their job ends once a human enters the cleanroom environment. It’s up to cleanroom personnel to follow cleanroom protocols correctly and consistently in order to keep the cleanroom clean.

Myth

: Anyone can clean a cleanroom.

Reality:

Cleanroom maintenance and upkeep is not the place to cut corners. Anyone working in a cleanroom, including the cleaning staff, needs to be thoroughly and consistently trained on specific cleanroom protocol. This includes how to enter and exit the cleanroom, checklists for daily, weekly, and monthly cleaning routines, and approved cleaning solutions and equipment.

_________________

Check out all the

myths about cleanroom revealed in this video

below:

Cleanroom Installation

Installing a cleanroom is a major commitment of your company’s time, money and resources.

However, if executed thoughtfully, cleanroom installation will be a worthwhile investment in your brand’s integrity. It could save you from product failure, costly recalls, and potential life-threatening consequences for your consumers.

There is no one right way to construct your cleanroom. The cleanroom specifications will depend on your industry, desired applications, and local environment.

What’s important is creating a cleanroom environment that is perfect for your needs and getting it right the first time.

The cleanroom installation process begins with an initial discussion among all stakeholders. Include personnel from production, maintenance, information technology and quality control. Brainstorm everyone’s needs as well as worse-case scenarios to prepare for.

Factoring the installation costs

Now, let’s get to the bottom line. How much will cleanroom installation cost?

Unfortunately, there is no clear cut answer to this question.

Modular cleanrooms can range anywhere from under $100 per square foot to over $1000 per square foot. Cleanroom manufacturers consider many variables when estimating cleanroom installation costs.

- ISO cleanroom classification | The lower the cleanroom classification, the cleaner the air needs to be. Efficient cleanroom systems are centered around cleanroom air. Therefore, the HVAC used to treat the air can represent up to half of the cleanroom installation cost.

- Space and Environment | How will personnel and equipment enter and exit the room? You will need entrances large enough to accommodate necessary equipment. Does your ISO cleanroom classification require antechambers, gowning rooms, or airlocks? Plan for at least one airlock for any room cleaner than ISO 8. What are the environmental conditions in the winter and summer months? Local weather conditions will impact your cleanroom’s air ventilation system.

- Cleanroom Materials | There is a range in costs for doors, windows, and the materials you choose for any horizontal or vertical surface (floors, walls, ceilings). Higher end choices will increase cleanroom installation costs.

Cleanroom manufacturing is just one piece of the budgeting puzzle.

Remember to include the recurring costs for maintaining and monitoring the cleanroom in your cleanroom installation plan.

A cleanroom installation plan includes:

- Installing a monitoring system to record the cleanroom conditions.

- Creating a plan for daily, weekly, and other periodic cleanings to maintain the specifications of your cleanroom classification.

- Staffing trained specialists who use approved cleaning solutions to maintain the cleanroom.

- Training all personnel who enter the cleanroom to use best practices.

- Monthly energy bills.

Be careful not to overspecify your cleanroom requirements (which could increase your monthly energy bills) or underspecify (which could limit future processes).

The better your cleanroom is constructed from the start, the easier it will be to maintain.

There are many factors to consider, and even small errors can dramatically impact the integrity of your cleanroom.

Partnering with a cleanroom performance testing contractor like Sure-BioChem Labs can help you avoid problems before they occur and help you stay in compliance with ISO standards. Then, you have to ultimately identify weak points in advance so that your cleanroom is fully functional from day one of operation.

Now You've Mastered Cleanrooms - What's Next?

A solid foundation on cleanroom classifications will give you a leg up on your industry’s research and manufacturing capabilities.

The first step is understanding the different types of cleanrooms, and which will work best for your industry and applications.

Once the cleanroom installation is complete, you’ll be able to utilize your cleanroom with confidence knowing the protocols for working in a cleanroom, monitoring your cleanroom air, and eliminating sources of contamination.

Whether you are looking for environmental monitoring of your cleanroom, cleanroom certification, cleanroom air testing, or training your personnel in best cleanroom practices for working in a cleanroom, Sure Bio-Chem Labs offers all the cleanroom services you need to run your cleanroom safely and efficiently.

Need Our Help? Fill Out a Service Request Today!

We're here to assist you with all your needs. Please complete our service request form to ensure we provide the best possible service.

It's quick and easy—tell us a little about your request, and our team will reply promptly. We look forward to serving you!

Blog Contact Page